|

市場調查報告書

商品編碼

1636462

義大利電動汽車電池分離器:市場佔有率分析、產業趨勢、成長預測(2025-2030)Italy Electric Vehicle Battery Separator - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

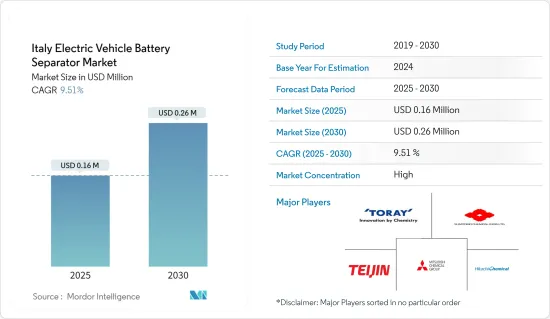

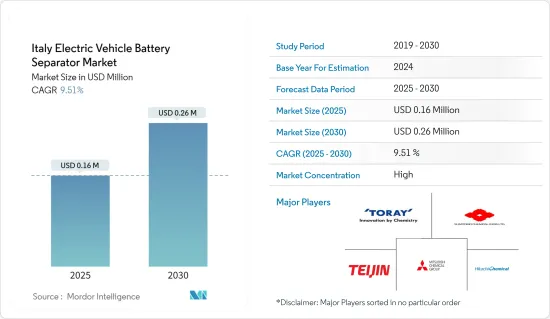

義大利電動車電池隔膜市場規模預計到2025年為16萬美元,預計2030年將達26萬美元,預測期內(2025-2030年)複合年成長率為9.51%。

主要亮點

- 從中期來看,電動車的普及和鋰離子電池價格的下降預計將在預測期內推動市場發展。

- 另一方面,一些國家的壟斷造成的電池材料供應鏈差異(例如原料短缺和分銷瓶頸)預計將抑制未來市場的成長。

- 其他電池化學材料(例如固體電池、先進鋰離子化學材料和鈉離子電池)的研發進展預計將為未來的市場提供機會。

義大利電動汽車電池隔膜市場趨勢

電動車的普及正在推動市場

- 在義大利,電動車(EV)的需求快速成長,推動了電動車電池隔膜市場的成長。隨著國家將重點轉向清潔能源,電動車成為人們關注的焦點,商業興趣不斷增加。消費者日益成長的興趣是由日益增強的環境意識、擁有電動車的經濟效益以及電動車領域的技術進步所推動的。

- 最近,義大利電動車(EV)銷量大幅成長。國際能源總署(IEA)強調,2023年電動車銷量將達13.6萬輛,與前一年同期比較成長19.29%。消費者日益成長的偏好不僅將加速電動車的普及,還將擴大該地區對電池和電池隔膜的需求。

- 為了鼓勵電動車的普及,義大利政府推出了一系列獎勵和補貼。其中包括減稅、電動車購買津貼、增加充電基礎設施投資。這些舉措與歐盟 (EU) 減少碳排放和實現氣候變遷目標的更廣泛努力產生共鳴。

- 具體而言,義大利承諾在 2023 年以及 2023 年和 2024 年每年撥款 6.5 億歐元(7.09 億美元)。這筆資金旨在鼓勵購買電動和低排放汽車。該承諾還包括對插電式混合動力汽車和混合動力汽車的補貼,在符合某些標準的情況下,可能提供高達 4,000 歐元(4,368 美元)的補貼。這些激勵措施,包括退稅和基礎設施投資,預計將在不久的將來顯著增加對電動車電池的需求,進而增加對電池隔膜的需求。

- 此外,義大利汽車工業正在快速投資電動車生產。隨著義大利公司向電動車製造領域擴張,對優質電池組件(尤其是隔膜)的需求大幅增加。這一成長凸顯了該行業對創新和永續性的奉獻精神。

- 例如,法拉利於 2024 年 4 月開設了一個最先進的實驗室,專門用於鋰電池研究,並計劃在 2025年終前推出一款全電動超級跑車。該設施將與博洛尼亞大學合作,深入研究固體、快速充電、熱充電以及確保電池安全和性能。此類措施不僅對於擴大該地區電動車的續航里程至關重要,而且對於推動電動車電池隔膜市場的擴張也至關重要。

- 鑑於這些發展,我們認為,在預測期內,電動車的需求以及相應的電動車電池隔膜需求的快速成長將保持穩定。

鋰離子電池類型主導市場

- 鋰離子電池以其高能量密度、長循環壽命和低自放電率而聞名,是電動車(EV)的首選。這種壓倒性的偏好不僅推動了電動車電池隔膜市場的成長,也塑造了電動車產業更廣泛的發展軌跡。

- 主要市場參與企業正在增加研發投資和產能,加劇競爭並降低價格。彭博社NEF指出,儘管整體上漲,但電動車電池組和電池能源儲存系統(BESS)的平均價格在2023年將大幅下降。價格跌至139美元/kWh,跌幅13%。這一趨勢預計將持續下去,到 2025 年降至 113 美元/千瓦時,到 2030 年降至 80 美元/千瓦時。

- 鋰離子電池技術的進步,包括提高能量密度、增強安全性和提高充電效率,正在刺激新型隔膜材料的開發。這些隔膜旨在滿足鋰離子電池的高能量和熱量需求,其中安全性和可靠性是重中之重。這種需求不僅推動了創新,也放大了分離器市場的需求。

- 2023年6月,輝能宣布突破性的電池架構,標誌著鋰離子電池30年發展的重大飛躍。透過以陶瓷隔膜取代傳統的聚合物隔膜,輝能在電動車鋰離子電池領域樹立了新的標竿。預計此類突破將在未來幾年推動先進鋰電池隔膜的需求激增。

- 義大利快速發展的超級工廠鞏固了主導歐洲電池市場的雄心壯志。這些主要用於生產鋰離子電池的大型設施正在增加對專用隔膜的需求。

- 2024年2月,Automotive Cells Company獲得了高達47億美元的資金,用於在法國、德國和義大利建立三個鋰離子電池超級工廠。該計劃得到了 Stellantis、梅賽德斯-奔馳和帥福得(Total Energies 子公司)等行業巨頭的支持,其超級工廠設計不僅注重穩定的電池生產,而且注重可擴展性。這凸顯出可靠的分離器供應對於該地區的未來至關重要。

- 這些發展將導致預測期內鋰離子電池產量激增,以及電動車電池隔離膜需求大幅增加。

義大利電動汽車電池隔膜產業概況

義大利電動車電池隔膜市場正在變得半固體。主要企業(排名不分先後)包括三菱化學集團株式會社、日立化成株式會社、東麗工業株式會社、住友化學株式會社、帝人株式會社。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 調查範圍

- 市場定義

- 研究場所

第 2 章執行摘要

第3章調查方法

第4章市場概況

- 介紹

- 2029年之前的市場規模與需求預測(單位:美元)

- 最新趨勢和發展

- 政府法規和措施

- 市場動態

- 促進因素

- 電動車的擴張

- 降低電池原物料成本

- 抑制因素

- 供應鏈缺口

- 促進因素

- 供應鏈分析

- PESTLE分析

- 投資分析

第5章市場區隔

- 電池

- 鋰離子

- 鉛酸

- 其他

- 材料類型

- 聚丙烯

- 聚乙烯

- 其他材料類型

第6章 競爭狀況

- 併購、合資、聯盟、協議

- 主要企業策略

- 公司簡介

- Mitsubishi Chemical Group Corporation

- Hitachi Chemical Company Ltd

- Toray Industries Inc.

- Sumitomo Chemical Co. Ltd

- Teijin Ltd

- Solvay SA

- EniChem

- Italvolt SpA

- 其他知名公司名單

- 市場排名分析

第7章 市場機會及未來趨勢

- 增加其他電池化學物質的研究和開發

簡介目錄

Product Code: 50003729

The Italy Electric Vehicle Battery Separator Market size is estimated at USD 0.16 million in 2025, and is expected to reach USD 0.26 million by 2030, at a CAGR of 9.51% during the forecast period (2025-2030).

Key Highlights

- Over the medium period, the growing adoption of electric vehicles and the decreasing price of lithium-ion batteries is expected to drive the market in the forecast period.

- On the other hand, the supply chain gap in battery materials created by the monopolies of some countries, such as ingredient shortages or distribution bottlenecks, is expected to restrain market growth in the future.

- Nevertheless, the increasing research and development of other battery chemistries like solid-state batteries, advanced lithium-ion chemistry, Sodium-ion batteries, etc, are expected to create an opportunity for the market in the future.

Italy Electric Vehicle Battery Separator Market Trends

Growing Adoption of Electric Vehicles Drives the Market

- In Italy, the surging demand for electric vehicles (EVs) is propelling the growth of the EV battery separator market. As the country pivots towards clean energy, the spotlight is firmly on electric vehicles, a segment drawing heightened attention from companies. This escalating consumer interest is fueled by heightened environmental consciousness, the economic benefits of owning an EV, and technological strides in the EV domain.

- Recently, Italy has seen a notable uptick in electric vehicle (EV) sales. The International Energy Agency (IEA) highlighted that in 2023, EV sales hit 136,000 units, a 19.29% jump from the previous year. This rising consumer inclination not only accelerates EV adoption but also amplifies the demand for batteries and battery separators in the region.

- To bolster electric vehicle adoption, the Italian government has introduced a suite of incentives and subsidies. These encompass tax breaks, financial grants for electric car purchases, and bolstered investments in charging infrastructure. Such initiatives resonate with broader European Union endeavors to mitigate carbon emissions and achieve climate targets.

- Specifically, in 2023, Italy pledged an annual allocation of EUR 650 million (USD 709 million) for both 2023 and 2024. This funding aims to stimulate purchases of electrified and low-emission vehicles. The commitment includes subsidies for plug-in hybrids and hybrids, with potential grants reaching up to EUR 4,000 (USD 4,368) under certain criteria. These incentives, spanning tax rebates and infrastructure investments, are poised to significantly elevate the demand for EV batteries and, consequently, battery separators in the near future.

- Additionally, Italy's automotive landscape is witnessing a surge in investments channeled towards EV production. As Italian companies expand into EV manufacturing, there's a marked increase in the demand for premium battery components, particularly separators. This growth underscores the industry's dedication to both innovation and sustainability.

- For example, in April 2024, Ferrari inaugurated a state-of-the-art laboratory dedicated to lithium battery cell research, aiming to roll out its inaugural full-electric supercar by the close of 2025. Collaborating with the University of Bologna, the facility will delve into solid states, rapid charging, thermal charging, and ensuring cell safety and performance. Such initiatives are not only broadening the electric vehicle lineup in the region but are also pivotal in driving the expansion of the EV battery separator market.

- Given these developments, the trajectory of EV demand and the corresponding surge in the need for EV battery separators during the forecast period appears robust.

Lithium-Ion Battery Type Dominate the Market

- Li-ion batteries, known for their high energy density, long cycle life, and low self-discharge rate, are the preferred choice for electric vehicles (EVs). This dominant preference not only propels the growth of the EV battery separator market but also shapes the broader trajectory of the electric vehicle industry.

- Key market players are boosting their R&D investments and production capabilities, intensifying competition and driving prices down. Bloomberg NEF highlights that, despite a general uptick in average battery pack prices for EVs and battery energy storage systems (BESS), 2023 witnessed a significant drop. Prices fell to USD 139/kWh, marking a 13% decrease. Projections suggest this trend will persist, with prices anticipated to reach USD 113/kWh by 2025 and plummet further to USD 80/kWh by 2030, driven by relentless technological and manufacturing advancements.

- Advancements in lithium-ion battery technology-like increased energy density, enhanced safety, and better charging efficiency-are catalyzing the development of new separator materials. These separators, designed to meet the high energy and thermal demands of Li-ion batteries, prioritize safety and reliability. This demand not only fuels innovation but also amplifies the need in the separator market.

- In June 2023, ProLogium introduced a revolutionary battery architecture, marking a significant leap in 30 years of lithium-ion battery evolution. By replacing the conventional polymer separator film with a ceramic variant, ProLogium has set new benchmarks in the lithium-ion battery domain for EVs. Such breakthroughs are anticipated to surge the demand for advanced lithium battery separators in the coming years.

- Italy's burgeoning gigafactories underscore its ambition to dominate Europe's battery landscape. These expansive facilities, primarily dedicated to Li-ion battery production, are amplifying the demand for specialized separators.

- In February 2024, the Automotive Cells Company secured a whopping USD 4.7 billion in funding to establish three lithium-ion battery gigafactories in France, Germany, and Italy. This initiative, backed by industry giants like Stellantis, Mercedes-Benz, and Saft (a TotalEnergies subsidiary), boasts a gigafactory design that emphasizes not just steady battery production but also scalability. This highlights the critical need for a reliable separator supply in the region's future.

- Given these developments, the production of lithium-ion batteries is set to surge, leading to a significant uptick in the demand for EV battery separators during the forecast period.

Italy Electric Vehicle Battery Separator Industry Overview

Italy's electric vehicle battery separator market is semi-consolidated. Some key players (not in particular order) are Mitsubishi Chemical Group Corporation, Hitachi Chemical Company Ltd, Toray Industries Inc., Sumitomo Chemical Co. Ltd, and Teijin Ltd, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Growing Adoption of Electric Vehicles

- 4.5.1.2 Decline in cost of battery raw materials

- 4.5.2 Restraints

- 4.5.2.1 The Supply Chain Gap

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 PESTLE ANALYSIS

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery

- 5.1.1 Lithium-ion

- 5.1.2 Lead-Acid

- 5.1.3 Others

- 5.2 Material Type

- 5.2.1 Polypropylene

- 5.2.2 Polyethylene

- 5.2.3 Other Material Types

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 Mitsubishi Chemical Group Corporation

- 6.3.2 Hitachi Chemical Company Ltd

- 6.3.3 Toray Industries Inc.

- 6.3.4 Sumitomo Chemical Co. Ltd

- 6.3.5 Teijin Ltd

- 6.3.6 Solvay S.A.

- 6.3.7 EniChem

- 6.3.8 Italvolt S.p.A.

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increasing Research and Development of Other Battery Chemistries

02-2729-4219

+886-2-2729-4219